Production method of Glycolic acid 99%

- 获取链接

- X

- 电子邮件

- 其他应用

Production method of Glycolic acid 99%

Glycolic acid is an important organic synthesis intermediate and chemical product. As a new type of fine chemical intermediate, it has many uses, as follows:

It can be used as a tanning assistant, water disinfectant, milk shed disinfectant, boiler scale remover.

Glycolic acid can be used as a cleaning agent. A mixed acid composed of 2% glycolic acid and 1% formic acid is an efficient and low-cost detergent suitable for cleaning air conditioners.

It can produce fiber dyeing agents, detergents, welding agent ingredients, varnish ingredients, copper etchants, adhesives, petroleum demulsifiers, metal integrators.

Sodium and potassium salts of glycolic acid are used as additives in electroplating solutions. Other uses include electrolytic grinding, metal pickling and leather dyeing.

It can also be used as a chemical analysis reagent for organic synthesis and as a daily chemical additive instead of fruit acid.

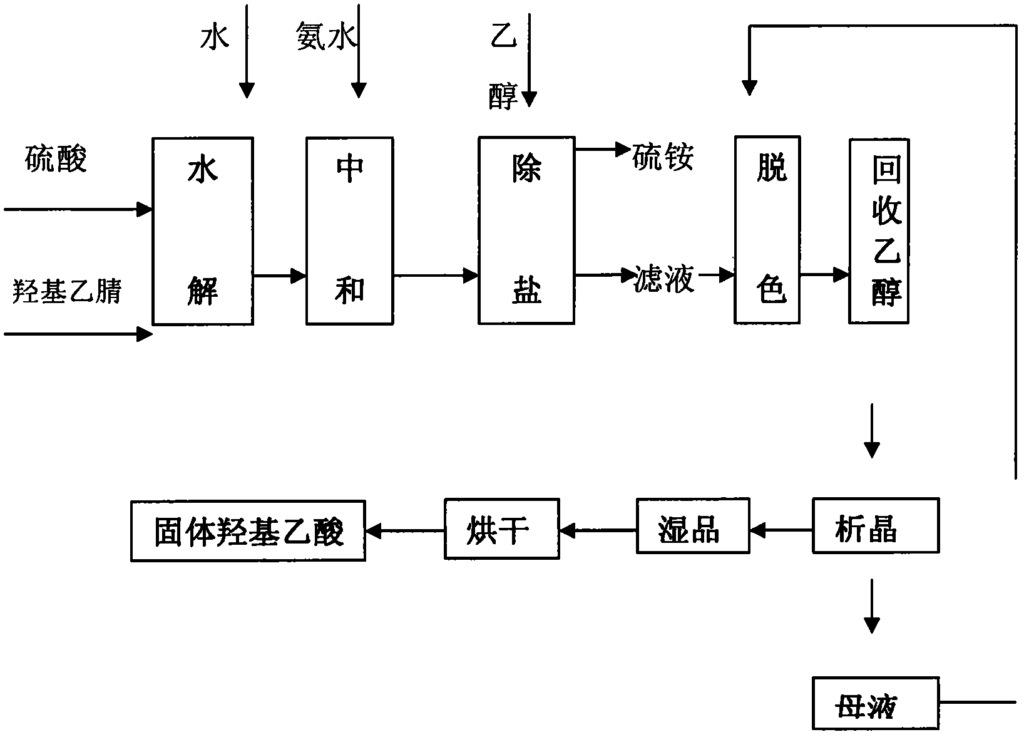

HOCH2CN+H20+H2SO4→ HOCH2COOH + NH4SO4

Glycolonitrile solution and Concentrated sulfuric acid molar ratio 1:1-2. Equipped with a thermometer, mechanical stirring, dropping funnel, reflux condenser, add concentrated sulfuric acid and certain water in flask.

Stir and add dropwise Glycolonitrile solution. After adding, the reaction is completed by holding at 100-150 ℃ for 6-8 hours. The mix of glycolic acid and aqueous ammonia obtains.

2. aqueous ammonia neutralization

Make the above reaction feed liquid is cooled to room temperature. Slowly add concentrated ammonia water in it, stir until neutral.

3. Demineralization

Add glycolic acid to the neutralized feed liquid, 5 to 10 times molar amount of Ethanol absolute, 10 ppm Glycolonitrile. Stir for 0.5 to 1 hour at room temperature, remove salt by suction filtration, and remove sulfur. The filtrate is an aqueous solution of glycolic acid and ethanol. Add certain injection carbon, decolorization, a colorless transparent liquid obtains.

4. Recovery of ethanol

Atmospheric pressure, dealcoholization until material temperature of 50-70℃. Conduct high vacuum ethanol recovery under vacuum of 1-10 KPa. Stop recycling until the material temperature is between 50-70℃.

5. Crystallization, Drying

After recovering ethanol, the feed liquid is slowly cooled to 1 degree per minute, and crystallization begins. When the temperature of the feed liquid reaches 0-20℃, the cooling stops.

Keep it at this temperature for 1 hour, conduct suction filtration at this temperature, and wash the filter cake with a little ice water to form glycolic acid wet product. Dry under low temperature and high vacuum, high purity solid glycolic acid obtains.

- 获取链接

- X

- 电子邮件

- 其他应用

评论

发表评论